Senasic cutting-edge technology: Universal Sensor Interface Chip USI — SNU501

In the previous issue, we introduced the capacitive sensor interface chip SNU301. In this issue, we will introduce another resistor sensor interface chip from SENASIC: SNU501.

With the continuous development of integrated circuits and technological information, sensors are playing an increasingly important role in industries, smart devices, and automotive electronics. Resistive sensors, with significant advantages such as high accuracy, fast response, and low cost, are widely favored by the industry.

SNU501 is precisely such a chip capable of driving resistive bridge pressure sensors. This chip is used for measuring pressure and temperature. It collects pressure data through internal high-resolution ADC, temperature compensation, and pressure compensation, providing calibrated pressure data directly. Additionally, SNU501 supports a wide operating temperature range of -40°C to 150°C, integrates reliability

designs like power reverse connection protection, has undergone AEC-Q100 automotive-grade testing, meeting strict automotive application requirements.

working principal

Resistive sensors come in a wide variety and are extensively used for measurements in displacement, angle, vibration, velocity, pressure, composition analysis, and medium characteristics, among others.

SNU501 can drive resistive bridge sensors, measuring changes in resistance values, and outputting proportionate voltage values or SENT signals after calibrated calculations.

Application Scenarios

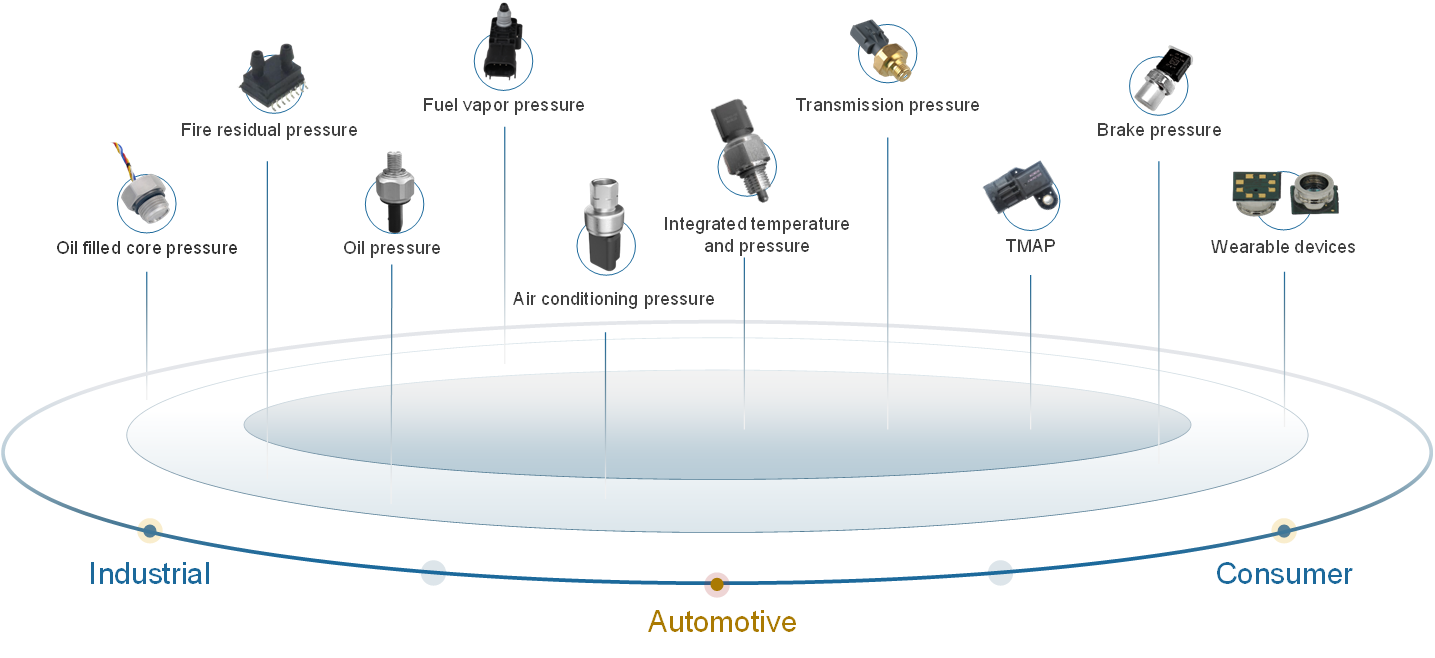

SNU501 can be widely applied in various fields, with particularly significant applications in automotive regulations

Industrial

It can be used for pressure measurements in equipment such as gas pipelines, oil pipelines, water supply and drainage systems, and thermal systems.

Electronic Products

It can be applied for pressure sensing detection in flow meters, water meters, gas meters, electronic medical devices, consumer electronics, drone altimeters, and white goods appliances.

Automotive

The applications of pressure and temperature measurements are widely distributed across various areas such as engine control, air conditioning systems, oil circuit control, transmission control, and chassis control. They are indispensable components of the automotive signal chain

Depending on the range of pressure measurement, different measurement technologies and application scenarios are suitable:

1. Silicon piezoresistive sensors are suitable for pressure ranges below 1 MPa. They offer high sensitivity and can measure extremely small pressures, which is advantageous for completing automated large-scale production.

2. Ceramic piezoresistive sensors are suitable for pressure ranges between 1 MPa and 7 MPa. They are cost-effective, have relatively good compatibility with various mediums, and exhibit relatively low temperature drift.

3. Glass micro-fused sensors and sputtered thin film sensors are suitable for pressure ranges of 10 MPa and above. They have an integrated structure and good sealing properties.

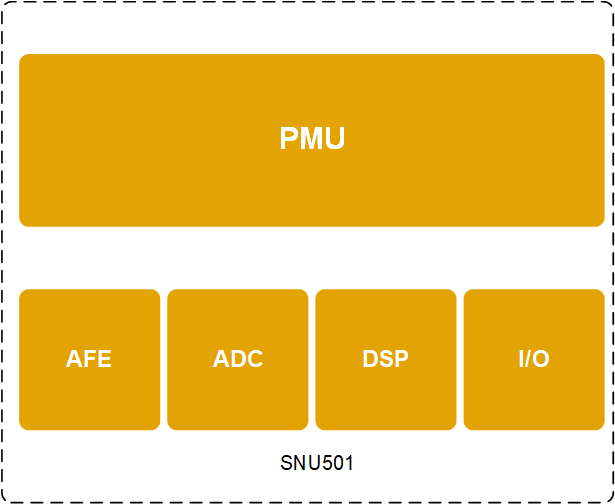

System Diagram

SNU501 consists of two main functional modules: power management and signal chain. The signal chain comprises several parts including analog front end, analog-to-digital conversion, digital signal processing, and output interfaces.

Features

Power Supply Voltage: 4.5V~5.5V

ESD HBM: ±2000V

Latch-up: ±200mA

OTP: 256Bytes

Built-in high-precision PGA

Built-in two channels of high-resolution 24-bit ADC

Built-in temperature sensor with external temperature sensor support

Supports analog diagnostic voltage output

Output Interface: Absolute voltage, proportional voltage, SENT

Package: SSOP16

Complies with AEC-Q100 Grade 0 certification

The Universal Sensor Interface (USI) chip from Senasic Electronics is primarily designed for automotive applications as a universal fully integrated programmable sensor interface chip. This chip can amplify, calibrate, and compensate the signals of almost all types of resistive bridge sensors (such as pressure sensors, strain gauges, and position sensors). By programming through connectors, the USI enables large-scale production of sensors to be assembled and then programmed, making it practical.

Senasic Electronics started the research and development of the Universal Sensor Interface (USI) product line in 2018, and it has already been successfully mass-produced. In the future, the company will continue to deepen its efforts in the field of chips, expand its footprint, break through barriers, and stay tuned for more developments.

For more product information and requirements for complementary development tools, please contact SENASIC technical support at

info@senasic.com.

* Some images are sourced from the internet. If there is any infringement, please contact us for removal.